Dry-running plates

Generally dry-running clutches and brakes use a pair of plates consisting of "organic" friction lining on one plate and a counterplate of steel or special cast iron. Although this friction combination is subject to wear, it has become a standard due to its hard wearing capabilities. Sintered, metallic friction linings are also used for particular applications. The friction linings described here are riveted or bonded to the plates in the form of rings or segments or are applied by a sintering process.

Wet-running plates

When considering "wet-running" plates, it is necessary to consider the lubricating and cooling oil, since this plays a decisive roll in the frictional process. In wet-running clutches and brakes the "classical" friction combination of steel/steel is today being replaced more and more by steel/sintered coating. The standard qualities of sintered coating are able to cover a wide range of conditions which are placed on high performance friction linings. In addition, the sinter is capable of being varied in terms of composition porosity and compatibility with oil enabling it to fulfill a wide range of special tasks. Of special interest within the range of wet- running plates is the friction combination steel/paper lining. This is being used to an ever greater extent in transmission systems in general mechanical engineering and in the motor vehicle industry. This is due to its extraordinary frictional behaviour and its almost total freedom from wear.

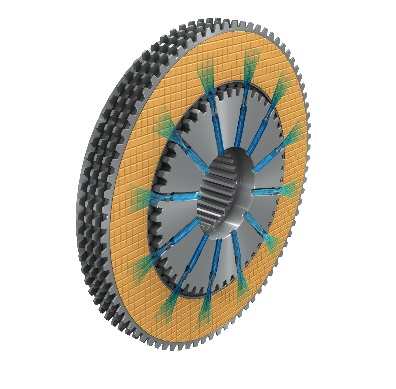

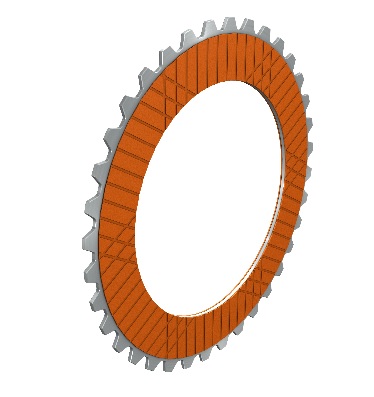

Wet-running sinter-lining plates

High thermal load

Broad power spectrum due to high allowable surface pressures

None to little wear

Hardened steel counterplate, typical with sinus corrugation

Good oil distribution via wafer or sunburst keyway

Applications:

- Press technology

- Marine main drives

- Brakes with high thermal loads

- Gearbox with high thermal loads

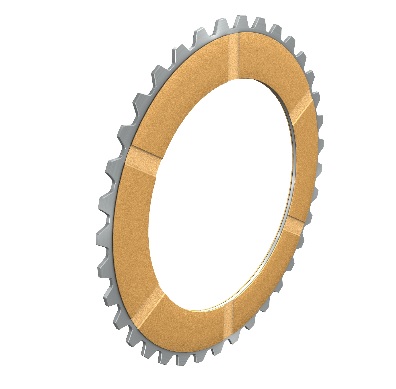

Dry-running sinter-lining plates

Medium thermal loads

High surface pressures

Low wear rates

Hardened counterplate, flat steel plates

Radial keyways for removal of abraded material

Applications:

- Brakes

- Clutches

- Slip clutches

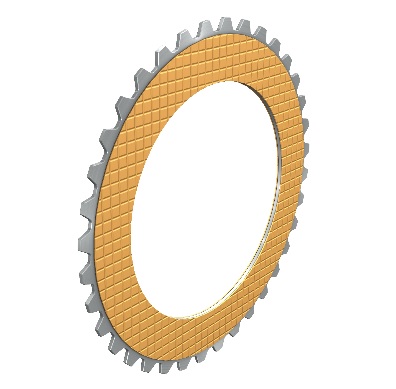

Wet-running paper plates

Moderate to high thermal load

Low surface pressures

Low to moderate wear properties

Constant friction value via speed, good controllability

Steel counterplate with sinus (hardened and unhardened)

Good comfort behavior

Oil distribution via group parallel or wafer keyway

Applications:

- Winding

- Unwinding jig with continuous slip operations

- Controlled overload clutches

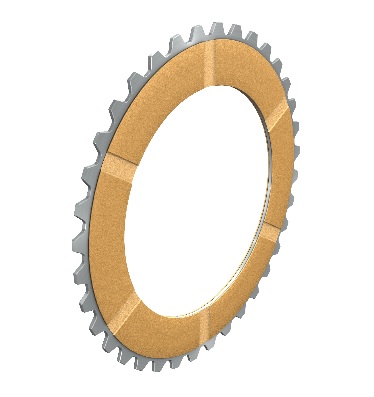

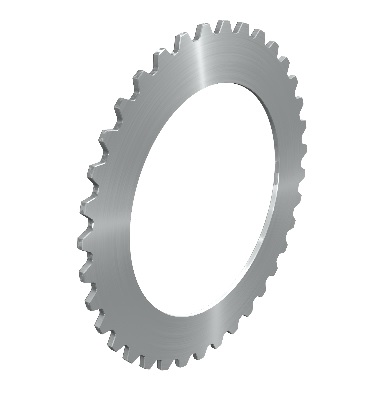

Dry-running organic-lining plates

Moderate thermal load capacity

High friction values

Moderate to high wear

Steel or cast iron counter friction surfaces

Applications:

- Brakes

- E clutches

- Pneumatic combined c/b

- Overload clutch

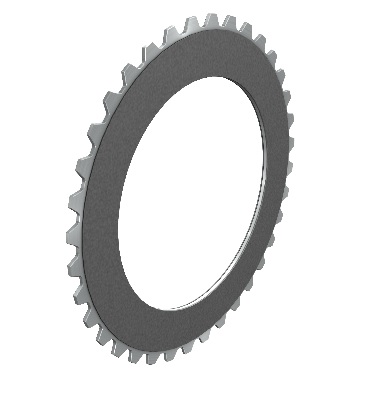

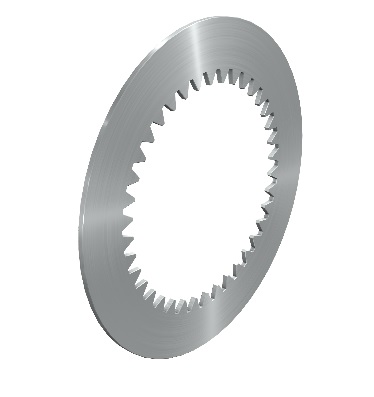

Steel plates

Version with sinus or flat

In hardened or unhardened version

Coating possible (e.g. molybdenum)

Surface areas are furnished with specific structures

Plates with splines

High torque transmissibility

Self-centering

Low plate strength possible

Use in limited installation spaces

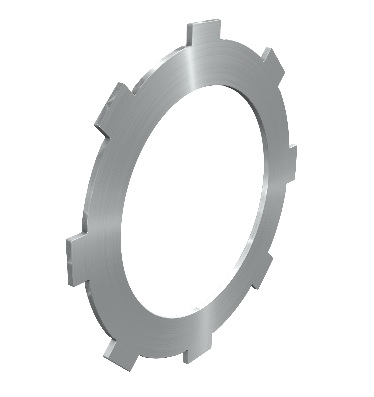

Plates with lugs

Counter profiles can be easily produced

Applications with small to medium torques

Applications:

- Small clutches and brakes

- E clutches/brakes

Dry-running organic-lining plates

Counter profiles can be easily produced

Applications with small to medium torques

Applications:

- Small clutches and brakes

- E clutches/brakes

Plates with rounded lugs

Counter profiles can be easily produced

Centering effect possible

Applications:

- Small clutches and brakes

- E clutches/brakes