Rotary indexers type RT

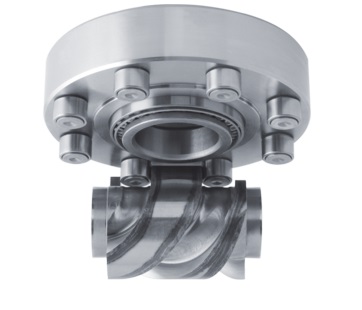

Rotary indexer type TT

The rotary indexer RT is often used in the assembly technology, the testing technology, the welding technology,

the printing, the pressing, the automotive industry, the microelectronics, the food industry, the medical and

the cosmetic industry.

Reliable, robust drum cam roundtable

for all applications

Construction diameter 100mm – 3500mm

Fixed divisions 2 – 96 or flexible

through NC technology

Switching times of 0.16s – 5s

Gentle starting and stopping across

the switching cam

Large, vertically hollow shaft

Standard accuracy 15" – 35"

New: Extreme indexing accuracy of 0.02mm

– Independent of the construction diameter

Four-point mounting at the outer diameter

of the output flange

Maintenance free through oil bath lubrication

Stop operation, continuous operation or

reversing design possible

All installation positions possible

The rotary indexer TT is often used in the assembly technology, the testing equipment, the welding technology,

the printing, the pressing, the automotive industry, the microelectronics, the food industry, the medical technology

and the cosmetic industry.

Reliable, robust drum cam roundtable

for all applications

Construction diameter 75mm – 2800mm

Fixed divisions 2 – 96 or flexible

through NC technology

Switching times of 0,16s – 5s

Gentle starting and stopping across

the switching cam

Large, vertically hollow shaft

Standard accuracy 15" – 35"

New: Extreme indexing accuracy of 0.02mm

– Independent of the construction diameter

Tapered rollers or cross roller bearing at the

inner diameter of the roll star

Low-cost variant with aluminum housing

Maintenance through oil bath lubrication

Stop operation, continuous operation or

reversing design possible

All installation positions possible

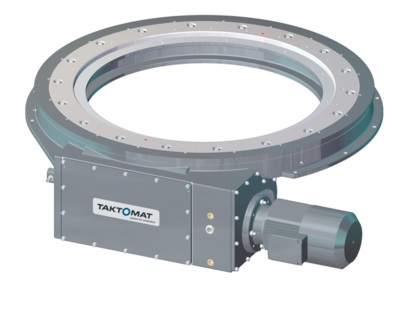

Switching ring TSR

Parallel gears XP, TP and SP

The switching ring TSR is often used in the assembly technology, the testing technology, the welding technology,

the printing, the pressing and in the automotive industry.

Reliable, robust switching ring for

all applications

Fixed divisions 4 – 96 or flexible

through NC technology

Very large center hole for e. g.

accommodation of minirobots

Very small roll star / output flange

(Relations innerØ to outerØ)

Extremely low / flat profile

Integrated countershaft

Four-point mounting at the outer diameter

of the role star

Maintenance through oil bath lubrication

The parallel gears are often used for clocking of straps and chains, swinging of gripper arms, converting rotary

to horizontal movements, rotating of components, separating and sorting.

Various design options of the cam

Short switching angles possible

Parallel input and output shafts

Pendulum possible

Very high accuracy through

backlash-free motion transfer

Gentle starting and stopping

Various cam laws possible

High reliability

Directions of rotating are reversible

Inexpensive clock drives

Adjustment of the shafts without eccentric,

because of that no skew of the shafts and

low adjustment effort

No skewing of the waves and low

adjustment effort

Maintenance through oil bath lubrication

Various installation positions possible