|

|

Link to Website  |

Download PDF Catalog |

| In a typical hydraulic press, the application fixes the duration of the work portion of the extension stroke. The only way to reduce the overall hydraulic cycle time is to increase the speeds of the non-working advance and retraction strokes. But to do this with conventional cylinders, large volumes of fluid must be moved at low pressure. This can be accomplished with multiple pumps, special hi-lo pumps, pre-fill valves, regenerative retraction arrangements (using 2:1 area ratios), and other special external circuits.

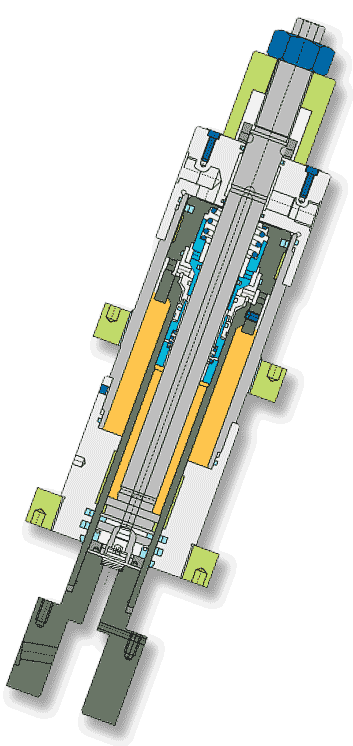

HydroQuick cylinders, designed and built by Lemacher Hydraulik, Taunusstein-Wehen, Germany, are double-acting units which allow for rapid advance and return strokes while supplied with constant pump flow. The main piston is bored out to hold a stationary secondary piston and rod fixed to the end cap. The annular chamber of the secondary piston is connected to a passage running the length of it's rod and leading to Port A. Internal pressure-actuated relief Valve R can connect the annular chamber to the quick return chamber behind the stationary piston. At rest, neither Port A nor B is pressurized, and valves M and R are closed. When external valving pressurizes Port B, and connects Port A to Port B, the main piston begins to stroke to the right, as represented in the top drawing. Valve M opens and fluid from the annular chamber lows into the main piston chamber (providing an internal regenerative circuit). Meanwhile, fluid is pushed from the quick-return chamber through Port B. The scaled volume on the opposite side of the secondary piston vents to atmosphere. |

|

1-888-EURODEX

Call or E-mail us today to see how effective Eurodex can be at satisfying your next European spare parts requirement!